The history of wire in the industrial sector dates back to the Middle Ages. Its manufacturing process consisted of beating metal sheets to give it the necessary thickness.

Later, they were cut into narrow strips and rounded by hammer blows. In this way, it was possible to convert it into wire, this technique being the most used until the 14th century.

The technique was improved through the manufacture of machinery that, through mechanical operations, these replaced the artisanal ones, which resulted in the speed, precision and performance of the manufacture of the wire.

This advance was a great step for the development and growth of the world wire industry, being of vital importance for the economy.

In Spain, the progress of wire accelerated in the 20th century. After the post-war period, there was an evolution in the wire process, experimenting with a great variety of new coatings and products such as wire in stainless steel. Subsequently, this process was carried out with optimal results in the industrial sector.

Wire is a product that is present in our daily life. From a simple mattress to the complex construction of a bridge, the wire is used in different sectors of the industry.

Wire applications in this sector

The applications of wire in this sector are wide and varied:

•Drawn wires are used primarily in general manufacturing. Its use is very widespread so it can be found in mattresses, armchairs, chairs, production of nets, baskets, meshes, automotive….

• In the mining industry, wire is used for the manufacture of cable for the purpose of drilling and excavating tunnels, wells and different uses of mining infrastructures.

• In the maritime industry, wire is transformed into maritime cables for drilling and oil production. It is also used for cranes for port use, to move containers, lift ships, and everything that involves mobility of heavy loads. Its use extends to mooring lines and lifeboats.

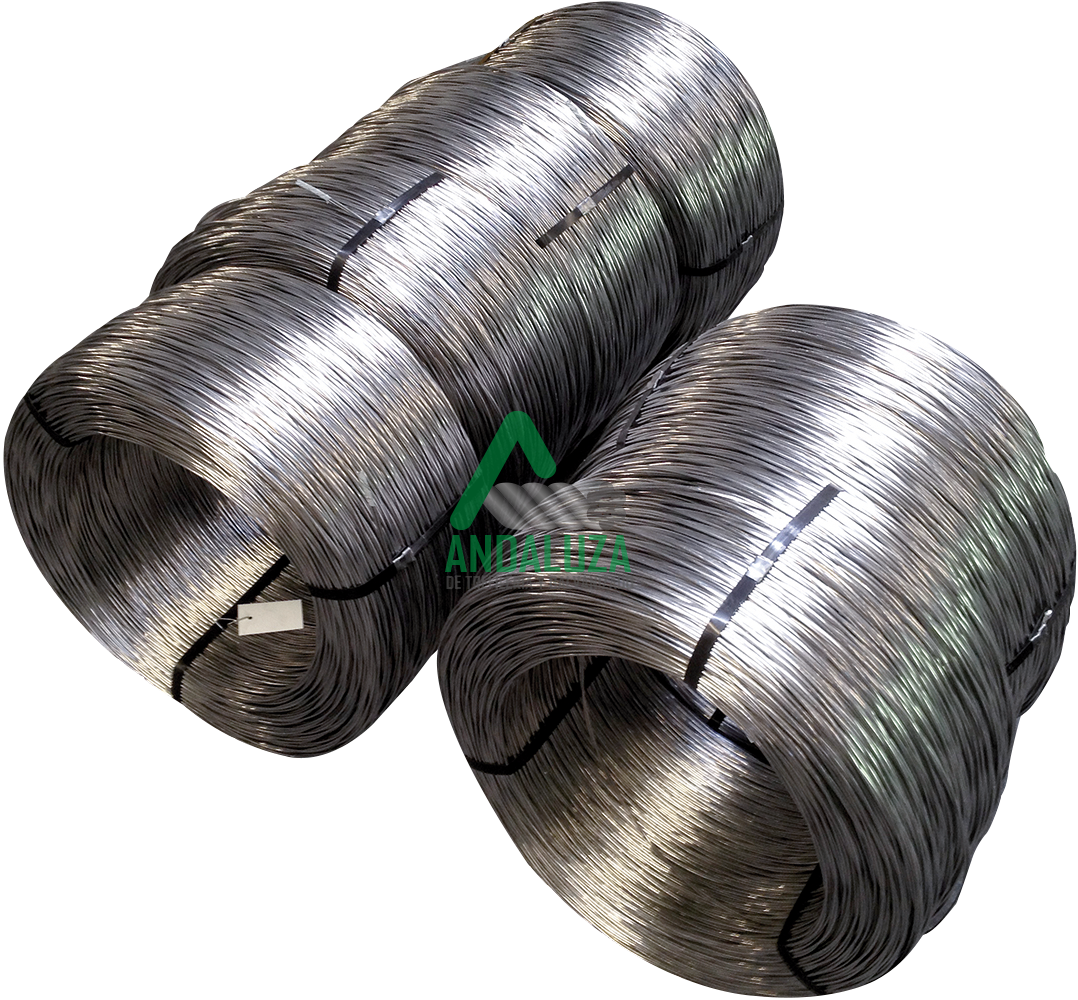

• In the construction industry its use is derived in the conformation of the use of cranes, mobility of heavy loads, ropeways, elevators and structural. The purpose is based on the subjection of different materials in height, being part of the design and the architecture formed. The main cable used is galvanized wire arranged in strong braided strands.

• Household and cleaning products. The wire industry is also present in household and cleaning products. Galvanized wire and drawn wire are worked through the perfect union of fine steel wires, thus achieving different shapes for specific uses. In this way, the wire reaches homes in order to be used for effective cleaning and order or as a raw material in some household appliances.

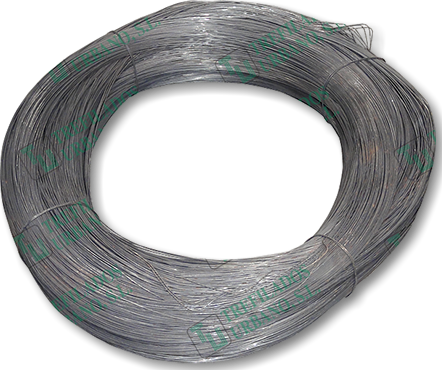

• Packaging processes. Galvanized wire is essential in packaging processes. Thanks to its versatility and ease of handling, the wire is used to tie and facilitate the transport process.

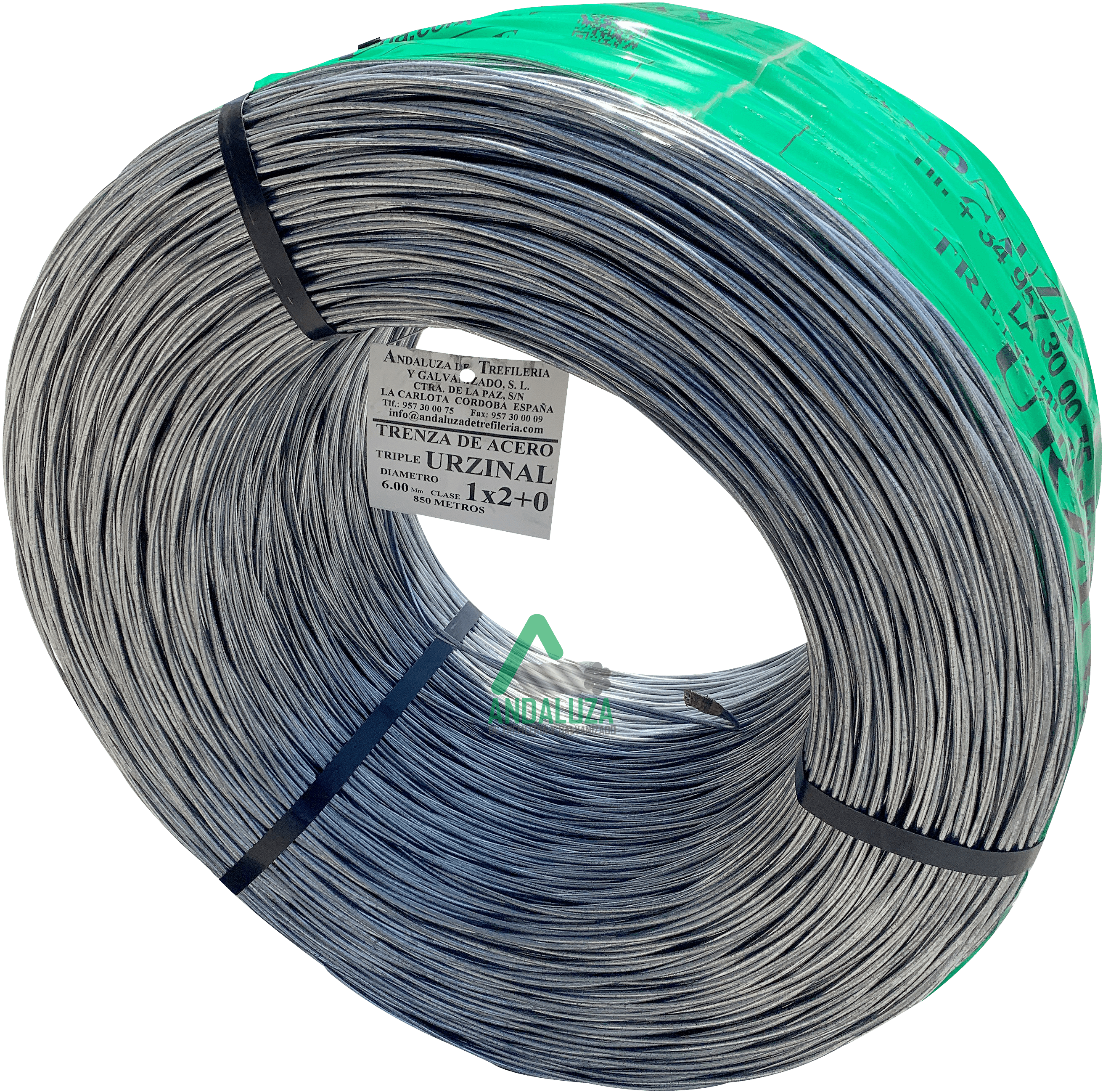

• In the electrowelding industry, the mesh is manufactured with drawn wire or Urzinal galvanized wire (zinc + Aluminum). These types of wire joined through electrowelding are used for industrial closings, fences, and home construction. Its purpose is based mainly on the delimitation or enclosures of specific areas.

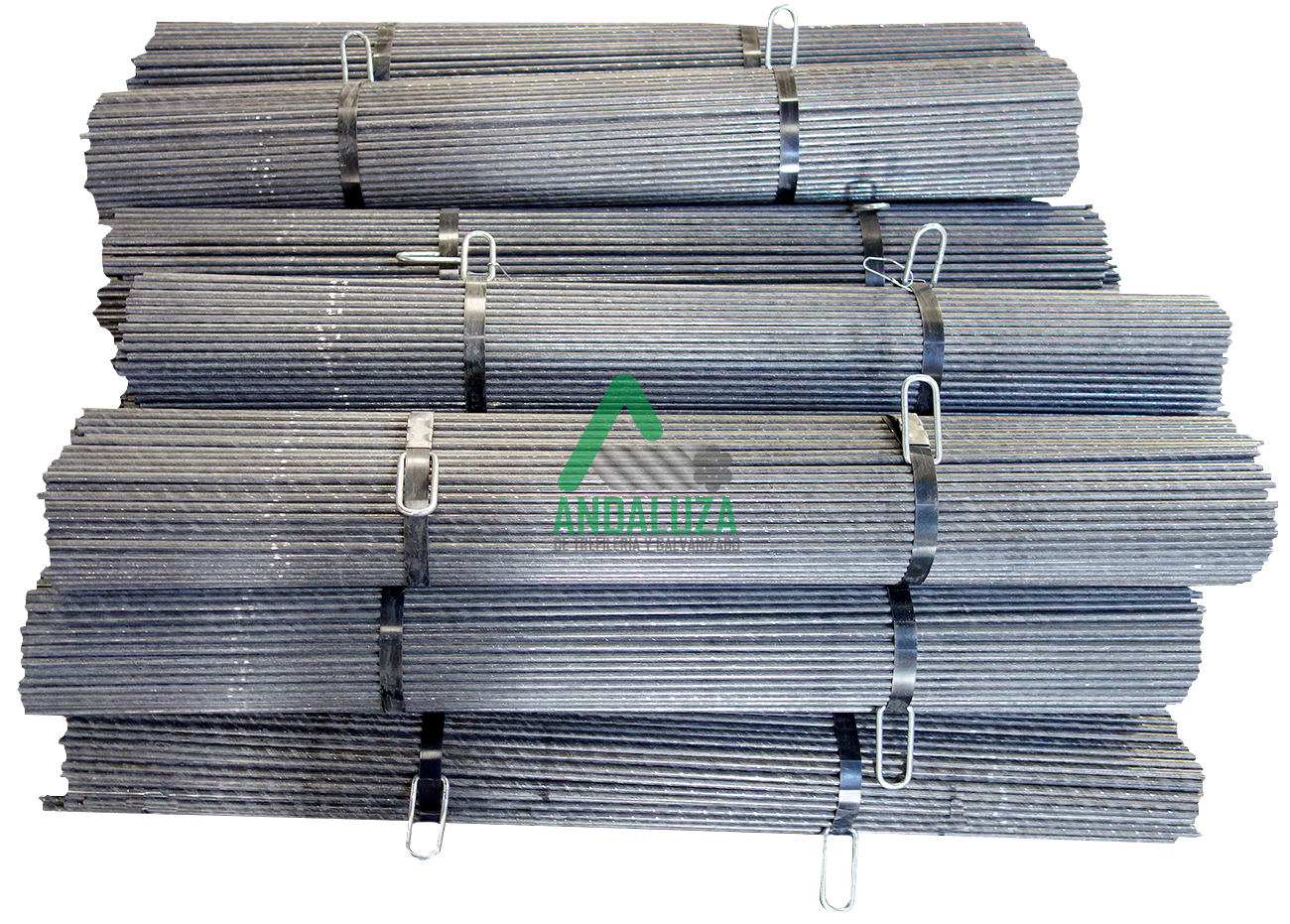

• In the recycling and recovery industry, black annealed steel wire is used for tying any type of product, with manual tying or automatic presses, to pack paper, cardboard, plastic, MSW, Cotton, textile fibers, polyester or any Recycled material also using the baller / Quick-links steel rod.

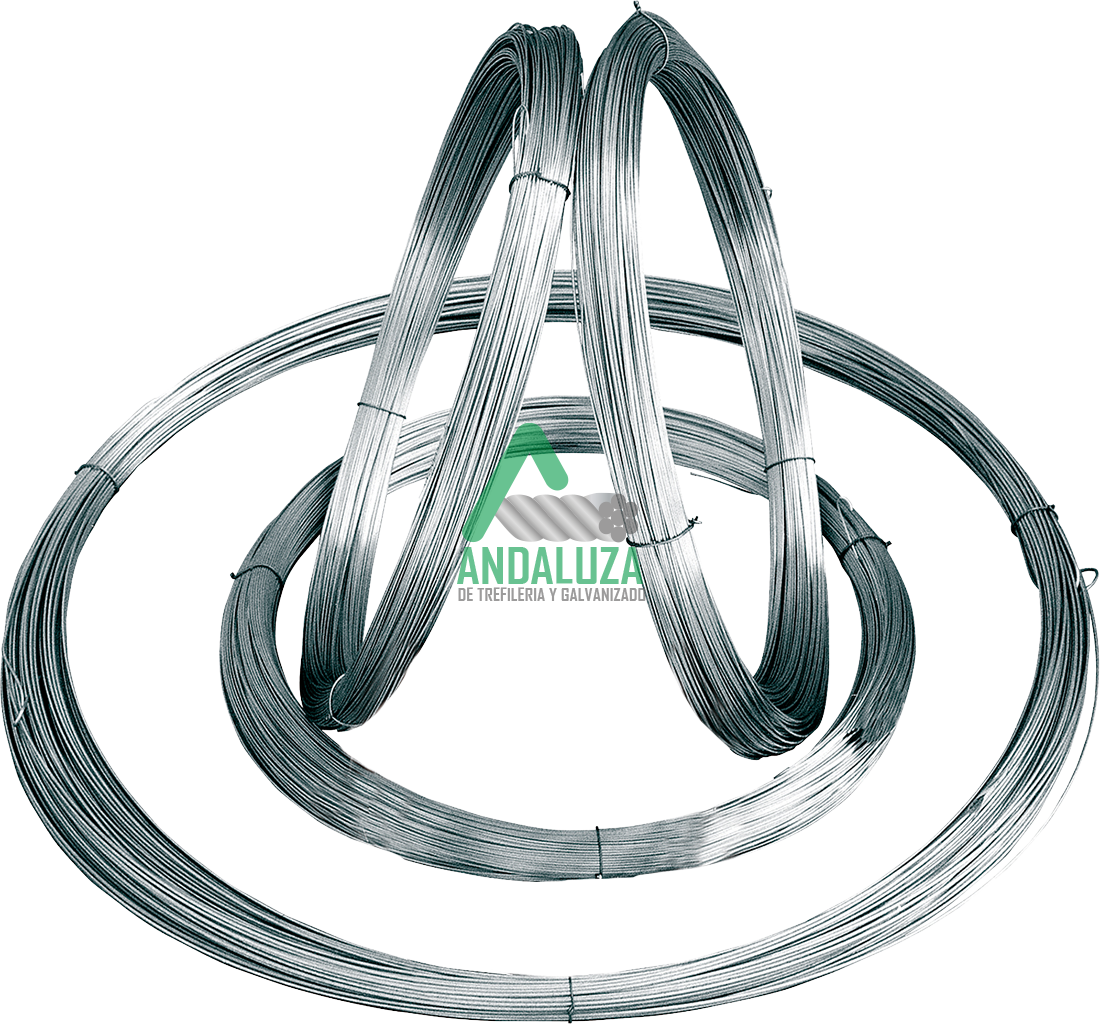

• In the industrial area it is as important to offer variety as quality of the product. At Andaluza de Trefilería, we offer coils of wire made according to the client’s needs in order to meet their objective.

Primary sectors

As we have seen, there are many sectors that depend on wire as a basic material that is part of their manufacturing processes.

Whether as part of machinery or tooling, steel wires or cables can even be used in the textile industry, in the manufacture of paper pulp, the manufacture of filters, electrical appliances, and even in recycling and waste plants.

For the tire sector, high carbon steel is used with a braided wire or bright drawn wire in order to form sheets and thus cover with elastomers.

In the cable industry, high-resistance wires are required with a homogeneous drawing, which guarantees their durability against extreme weather conditions. In this case, the most widely used product is ACSR galvanized wire or aluminum-coated steel wire for overhead lines given its ductility characteristics.

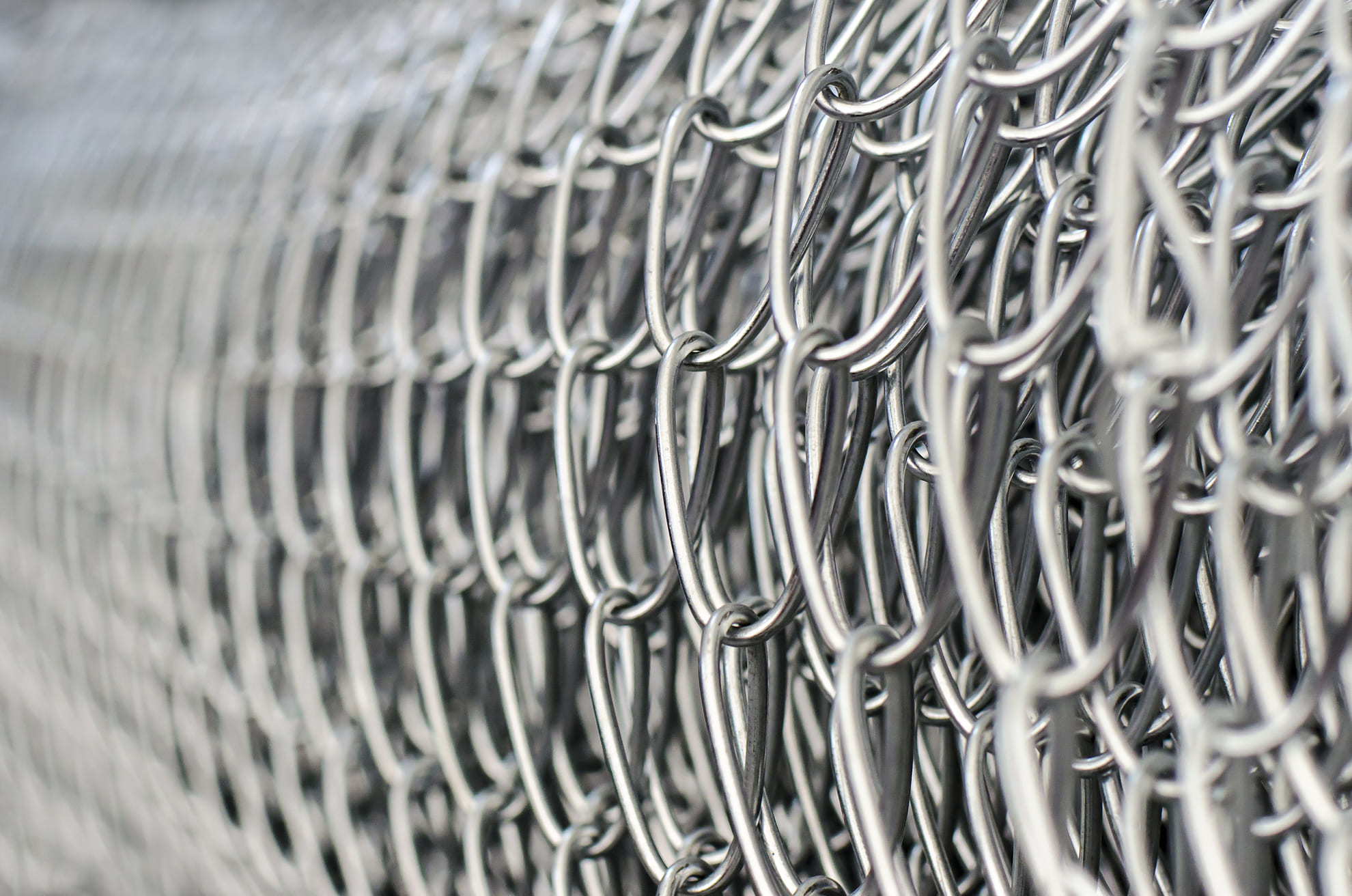

Stainless wire is used in spaces that require cryogenics, thanks to its high resistance to cold. Its use is also extended in order to withstand high temperatures as is the case in ovens in the hospitality sector.

Protection and security

Industrial wires are widely used to guarantee the protection and safety of the interior of enclosures. Its use extends mainly as perimeter fencing of the surface where the industry is located.

Torsion meshes, simple torsion meshes, wire panels, barbed wire, barbed wire, concertina, u staples and derived products are widely used for this purpose.

In relation to protection and safety, galvanized hard steel wire is used for the elaboration of fences or mobile construction panels due to its versatility and resistance and is highly moldable according to needs. These wires are characterized by their external zinc coating guaranteeing their durability without the need for maintenance.

Another very profitable option in protection and security is the use of stainless steel wire. In its smelting process, this material is melted and freed of its impurities, so it can be used for other purposes.

Because of its strength and toughness, high carbon steel and low carbon steel can be used. For electric fences, the use of galvanized DTG wire, oval wire or wire braid is ideal for its versatility.

All these products offer the necessary protection by providing security to your facilities and equipment, avoiding corrosion over time, thanks to their zinc coating that guarantees their long life.

Transformers

There are products derived from these industries that are partially or totally made with our wire. Its uses are wide and varied:

• Wire for electrowelded panels.

• Wire for cages.

• Wire for bales.

• Wire for tying in recycling presses.

• Zinc aluminum wire for cable trays

• Hangers.

• Mattress springs.

• Handles for buckets.

• Suction filters.

• Plugs.

• Electrowelded grids.

• Galvanized and gray wire rods.

• Zinc-aluminum barbed staples.

• Metal staples.

• Wavy meshes.

• Springs and wire springs.

• Galvanized steel cords, strand and cables.

The main product with which they are made is bright wire, galvanized steel or stainless wire in order to be transformed into other commercial products that, according to their properties, offer certain advantages such as resistance to corrosion and are more durable.

Personalized attention to our customers

At Andaluza de Trefileria y Galvanizado, our experts will always be with you. If you need advice, we will inform you about the steel cord that suits your needs and uses.

At Andaluza de Trefileria y Galvanizado, we offer our clients the possibility of manufacturing other diameters, tolerances and strengths.

Thanks to our R&D department, we are one of the main national and international suppliers in the wire industry.

All of our products are top quality. Our wires have an excellent lifetime guarantee and are manufactured according to ISO 9001 and ISO 14001 standards.

At Andaluza de Trefileria y Galvanizado we guarantee innovative solutions and a wide range of industrial wires and cables.

Do not hesitate to contact Andaluza de Trefileria y Galvanizado and bet on quality.